Addler has associated themselves with some of the following reputed international firms for their range of Industrial automation products as their Value Added Channel Partners.

AC Motor Drive Products Specifications

With modern power electronics and advanced microprocessor technology, Delta's AC Motor Drives are able to efficiently control motor speed, improve machine automation and save energy. Taking advantage of our strong position in power electronics technology, Delta's VFD Series of AC motor Drives has evolved rapidly. Each Drive series is designed to meet specific application needs. Our AC Drives accurately control speed and torque, smoothly handle an increased load, and provide numerous custom control and configuration operating modes. Our AC Motor Drive product line provides a full range of motor control technologies and is used throughout a wide range of industries, to enhance and improve machine automation.

AC Servo Motor and Drive Specifications

As the technology of microprocessor unit becomes more advanced and much further, the development and cost effectivity of permanent magnet manufacturing technology for servo motor and high power and high performance semiconductor power devices is improved continuously. Therefore, AC servo motor and AC servo control system have become the basic techniques for accomplishing automation control technology in current industry field.

Delta servo system is an omnibearing integrated servo system which is based on Delta's strength in industrial and electronic technology and developed for different customers' requirements of various application machine tools. All ASDA series servo drives are provided with a superior digital signal processor (DSP) which represents a high-speed performance of the control circuit loop. Besides, the other features of Delta ASDA series, including gain tuning, smooth motor operation and software analysis / monitor function, also provide high-speed and high-precision motion control for a wide range of industrial automation applications.

Programmable logic controller (PLC) Specifications

Programmable logic controller (PLC) is a control system using electronic operations. Its easy storing procedures, handy extending principles, functions of sequential/position control, timed counting and input/output control are widely applied to the field of industrial automation control.

Delta's DVP series high-speed, stable and highly reliable PLC's are applied in various automation machines. Besides its fast logic operations, abundant instructions, various extension cards and cost-effectiveness, DVP series PLC's support many communication protocols, seamlessly integrating the industrial automation control system as a whole.

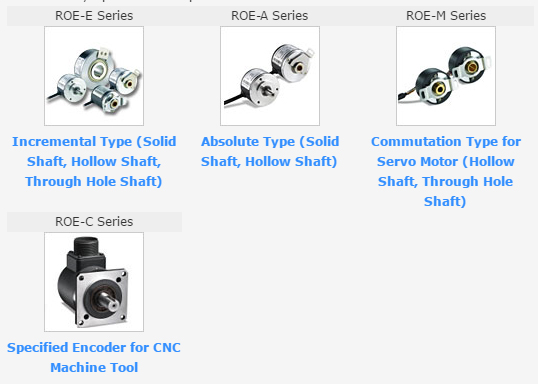

Rotary Optical Encoders Specifications

Rotary Optical Encoder is a sensor that converts machinery positional information into corresponding pulse numbers or digital data by photoelectric signals. Therefore, it can detect the speed, position, angular velocity, distance and counts information relating to mechanical machine. It is usually applied on the angle-measuring device and equipment. Hence, it is a very important device in industrial automation field.

Delta ROE series provides precise positioning and speed sensor function. Major applications include main hoist of crane (crane control), CNC tooling machine, elevator, conveyer, textile machine, and storage equipment, etc. industry related machine. Also, it can also be built inside of many kinds of servo motors, brushless DC motor (BLDC) and induction servo motors, and converts rotary motion or position to electronic pulse numbers for phase change, speed and position detection.

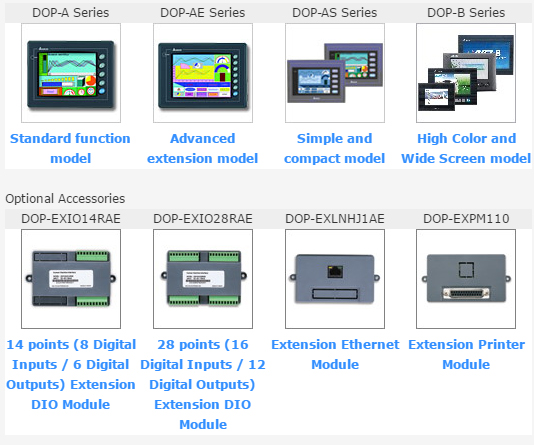

Human Machine Interface (HMI) Specifications

HMI (Human Machine Interface) is a medium for information exchange and mutual communication between electromechanical system's and the user. It allows the user to complete settings through touchable images or keys on the user-friendly window. This not only offer's fast and convenient control of manufacturing automation, but also has replaced traditional controlling panel's which needextensive wiring.

Delta DOP series Human Machine Interface provides various touch screens with multiple dimensions and colors and it also offers fast and convenient control functions for industrial automation machines. Moreover, programming the whole DOP series is done using the Delta Windows-based and user-friendly Screen Editor software. By using this software, the user can quickly edit images and graphs and set suitable communication protocol through Macro command.

Temperature Controller Specifications

Temperature controller is a measurement device used on temperature control. Thermocouple-type and resistor-type temperature controllers measure temperature electronically, obtaining the temperature change from the sensor and sending the measured data to the electronic processor. The output device will then control the temperature variation within a specific range.

Delta's DT series temperature controller has fast output response, accurate PID parameter auto-tuning, support Modbus communication protocol and is built-in with various output types, allowing different systems to reach a stable control status very quickly. Besides, all series are complied with international installation dimension and CE, UL international safety approvals.

Timers, Counters, & Tachometers

Features : CTA Timer/Counter/Tachometer features easy and handy parameter settings and tuning and are certified by international standards CE and UL.

Specification:

- Panel size: 48mm × 48mm

- Power input: 100~240VAC, 50/60Hz

- Range of input voltage: 85%~110%, rated voltage

- Power consumption: less than10VA

- External power supply: 12VDC ± 10%; 100mA

- Display: Double-line 6-digit LCD display

- NPN input: ON impedance 1K ohm max. ON residual

- voltage: 2V max.

- PNP input: high level: 4.5~30VDC; low level: 0~2VDC

- Dielectric strength: 2,000VAC; 50/60Hz for 1 minute

Applications: Label printers, cut-to-length machines

Industrial Communication Module

In the applications of industrial automation, communication modules are used as connectors for sending different electric signals, including converting RS-232, RS-422/485 signals and making the series information of servo and control devices compatible with one another.

Delta's IFD series industrial communication module is stable and high quality, built-in with signal short-circuited and transient overvoltage protection. Besides multiple installation methods, its excellent signal processing and isolation ensure correct data transmission.

IFD9506 and IFD9507 are able to connect the communication device supporting only serial communication to the Ethernet, and both are equipped with RS-232/485 interface. Different from other Gateway products in the market, IFD9506 and IFD9507 are designed with enhanced noise immunity and handiness. The users therefore are able to connect Delta's AC motor drive, PLC, human machine interface, servo motor, temperature controller and other industrial automation products to the Ethernet through IFD9506 (Modbus TCP) or IFD9507 (EtherNet/IP), and the software installed in the PC monitors and controls the entire network, which makes a complete and user-friendly network monitoring solution.

Besides the traditional Modbus communication module, Delta also developed other field bus communication module including DeviceNet and CANOpen. DNA02 / COA02 can be applied to the connection between DeviceNet / CANOpen and self-defined equipments with Modbus protocol.

IFD6500 is a convenient RS-485-to-USB converter, which does not require external power-supply and complex setting process. It supports wide-ranging baud rate of 75~115.2kbps, automatically switching data exchange direction. In addition, it adopts RJ-45 as RS-485 connector for users to wire conveniently. And its tiny dimension, handy use of plug-and-play and hot-swap provide more conveniences while connecting all DELTA IABU products to your PC.